Ingenious Methods for Transformer Oil Purification and Improved Performance

Ingenious Methods for Transformer Oil Purification and Improved Performance

Blog Article

Transform Waste Into Value With Advanced Transformer Oil Recycling

The makeover of waste into worth presents a critical opportunity within the electric industry, particularly via the lens of innovative transformer oil recycling. By using advanced innovations, such as vacuum cleaner purification and filtration systems, companies can recuperate important resources from made use of transformer oil while alleviating environmental risks. This method not just boosts operational performance but likewise lines up with expanding sustainability demands. As industries increasingly prioritize environmentally friendly efforts, the effects of these sophisticated recycling techniques call for closer evaluation to understand their full capacity and influence on the marketplace.

Comprehending Transformer Oil

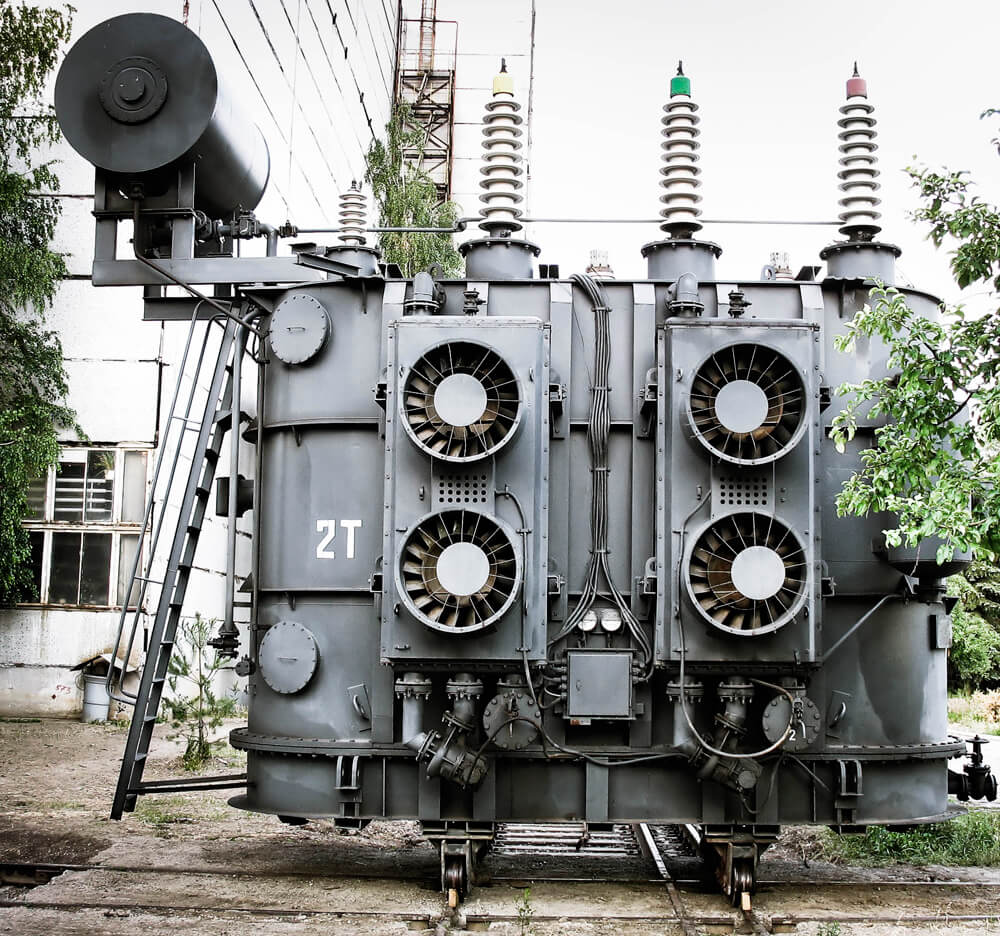

Transformer oil is a specialized insulating and cooling down fluid utilized in electrical transformers to improve operational performance and integrity. This oil plays a crucial function in avoiding electrical discharges and maintaining the required thermal equilibrium within the transformer - Transformer Oil Recycling. It serves to insulate the conductive elements, ensuring that power is efficiently moved while reducing the risk of brief circuits

Commonly stemmed from fine-tuned petroleum, transformer oil is characterized by its high dielectric toughness, low viscosity, and a durable chemical security that enables it to endure raised temperatures. The oil's ability to dissipate warmth produced throughout operation is crucial; as transformers convert electric energy, they generate heat that has to be efficiently taken care of to prevent equipment failure.

In addition, transformer oil is developed to stand up to oxidation and degradation, which can cause the formation of sludge and other harmful by-products. Normal monitoring of oil top quality is important, as pollutants can endanger its insulating residential or commercial properties and total performance. Comprehending the make-up and functionality of transformer oil is important for upkeep practices, guaranteeing the durability and operational integrity of transformers in various applications across the power sector.

Importance of Recycling

Why is reusing transformer oil important for both environmental sustainability and financial performance? The inappropriate disposal of transformer oil can lead to serious environmental risks, including soil and water contamination. By recycling this valuable resource, we not only alleviate these risks yet likewise add to a cleaner community. Utilized transformer oil contains hazardous materials that, if released right into the setting, can damage wild animals and interfere with local communities. Recycling assists to stop these negative impacts, strengthening the dedication to ecological stewardship.

From a financial perspective, recycling transformer oil offers considerable price savings for organizations. The process enables companies to recover a high-quality item that can be recycled in various applications, minimizing the need for buying brand-new oil.

Advanced Recycling Technologies

As the demand for lasting techniques in the energy market expands, advanced recycling modern technologies have emerged as an essential service for handling made use of transformer oil. These technologies include an array of cutting-edge methods developed to effectively redeem beneficial resources while reducing ecological influence.

One noticeable technique is vacuum distillation, article source which divides oil parts at reduced temperature levels, preserving the high quality of the base oil while eliminating pollutants. This approach boosts the recovery rate and ensures that the recycled oil meets market requirements. An additional substantial development is making use of adsorption and filtration systems, which use specialized materials to catch pollutants and bring back the oil's residential or commercial properties efficiently.

Additionally, the combination of chemical treatments, such as neutralization and decolorization, plays an important function in refining transformer oil. These processes remove acids, sludge, and discoloration, resulting in top quality recycled oil that can be reused in numerous applications.

Economic and Environmental Perks

The environmental and financial benefits of transformer oil recycling click resources are substantial, presenting a twin advantage for both sector stakeholders and environmental conservation. By reprocessing made use of transformer oil, business can considerably reduce functional costs connected with purchasing new oil, hence enhancing their profits. This process not just minimizes garbage disposal fees however additionally enables the recuperation of important products, generating extra earnings streams.

From an environmental point of view, reusing transformer oil adds to a reduction in contamination and source depletion (Recycling Transformer Oil). Appropriate recycling procedures minimize the risk of harmful spills and dirt contamination, safeguarding regional ecosystems and promoting biodiversity. Repurposing transformer oil decreases the demand for virgin oil extraction, which often entails environmentally devastating methods such as boring and refining.

Additionally, embracing innovative recycling innovations improves compliance with rigid ecological guidelines, therefore securing firms from possible responsibilities and penalties. The favorable influence on business social obligation efforts can improve a company's credibility, fostering greater trust and commitment amongst customers and stakeholders. Basically, the economic and ecological benefits of transformer oil recycling emphasize its value as a lasting practice in the energy field.

Future of Transformer Oil Recycling

Structure on the considerable economic and ecological advantages highlighted, the future of transformer oil recycling appears promising, driven by technical improvements and boosting regulatory pressures. Technologies in recycling modern technologies, such as improved filtration systems and chemical handling techniques, her response are expected to boost the effectiveness and effectiveness of oil recuperation processes. These advancements not just decrease waste yet likewise optimize the top quality of recycled oil, making it better for reuse in different applications.

Furthermore, as federal governments and regulatory bodies globally execute more stringent ecological guidelines, the demand for lasting practices will increase. This change will compel markets to adopt transformer oil recycling as an essential part of their operational approaches. Companies that focus on environmentally friendly techniques are likely to get a competitive edge, interesting environmentally mindful customers and stakeholders.

Conclusion

The recycling of transformer oil through advanced modern technologies not just saves important sources however likewise substantially reduces environmental threats connected with garbage disposal. By adopting cutting-edge approaches such as vacuum distillation and purification, the electrical industry can boost sustainability while concurrently decreasing operational expenses and generating profits. As the concentrate on environmentally friendly methods intensifies, the future of transformer oil recycling appears appealing, positioning firms to thrive in a significantly open market that focuses on sustainability and environmental duty.

Transformer oil is a specific cooling down and insulating liquid used in electric transformers to enhance functional performance and dependability. Recognizing the structure and capability of transformer oil is important for upkeep practices, making sure the long life and operational stability of transformers in various applications across the power sector.

One prominent method is vacuum cleaner purification, which separates oil elements at reduced temperatures, protecting the top quality of the base oil while getting rid of contaminants. By reprocessing made use of transformer oil, firms can considerably minimize functional costs associated with buying brand-new oil, hence improving their bottom line. Repurposing transformer oil reduces the need for virgin oil removal, which commonly involves environmentally damaging methods such as exploration and refining.

Report this page